Air compressors used for medical industries are specially designed to meet the demand of hospitals & clinics. Typically medical air compressors are built oil free advanced filtration systems and drying mechanisms to remove moisture, oil, and other impurities from the compressed air. This ensures that the compressed air produced by the oil free compressor is of high purity and suitable for medical use.

To meet the need for compressed air in hospitals and similar settings like clinics, laboratories & even in pharmaceuticals, Global Cynax offers Anest Iwata oil free reciprocating air compressors in Bangladesh exclusively. These compressors meet all the necessary requirements and regulations for hospital use.

In order to maintain consistent performance, Anest Iwata utilizes heat-resistant and thermosetting composite resin piston as a replacement for the conventional rider ring technology. This innovative piston design facilitates seamless functioning without encountering any seizing problems. Apart from Anest Iwata’s oil free compressors deploy patented and proven CRITICAL MAINTENANCE FREE (CMF) technology, the only of its kind in the world.

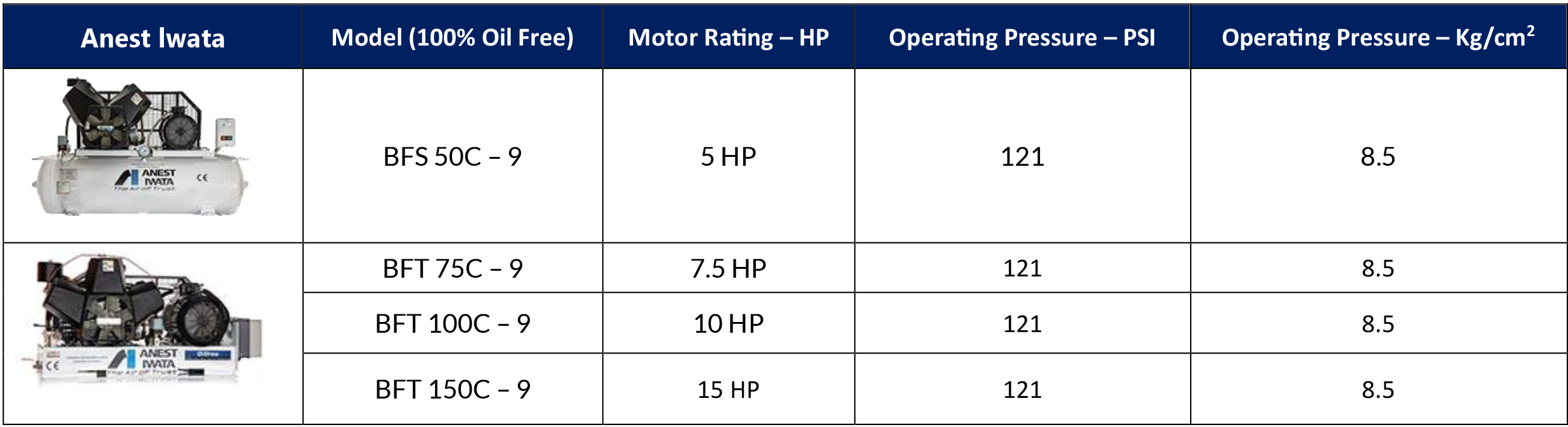

Base Mounted

Anest Iwata’s reciprocating compressors that are mounted on a base frame, with the air receiver tank being installed separately. Base frame mounted reciprocating compressors are commonly employed in situations that necessitate a larger or supplementary air storage tank. One notable advantage of this configuration is that it typically results in lower noise and vibration levels compared to tank-mounted compressors. Additionally, in certain instances, it allows for optimal utilization of available space by facilitating the separate installation of the storage tank. This arrangement provides flexibility in terms of positioning and enables more efficient use of the available floor area.

Tank Mounted

A tank-mounted compressor refers to a system in which the compressor is installed directly on the air storage tank. Global Cynax offers the capacity of the air receiver tank ranges from 180 liters to 280 liters, depending on the air compression & delivery capacity of the compressor. This configuration offers several advantages. Firstly, it enables better control and regulation of air pressure, resulting in a more consistent and stable air supply. The presence of the tank acts as a buffer, reducing pressure fluctuations and ensuring a reliable source of compressed air, particularly during periods of high demand. Additionally, this system helps to prevent short-cycling of the compressor, which not only reduces energy consumption but also minimizes wear and tear on the equipment, leading to improved longevity and efficiency.